Our Product

At GTHR Poland, we produce electrolyte for lithium-ion batteries, which plays a key role in the process of energy storage and transfer.

Lithium-ion battery - key features of the battery and electrolyte

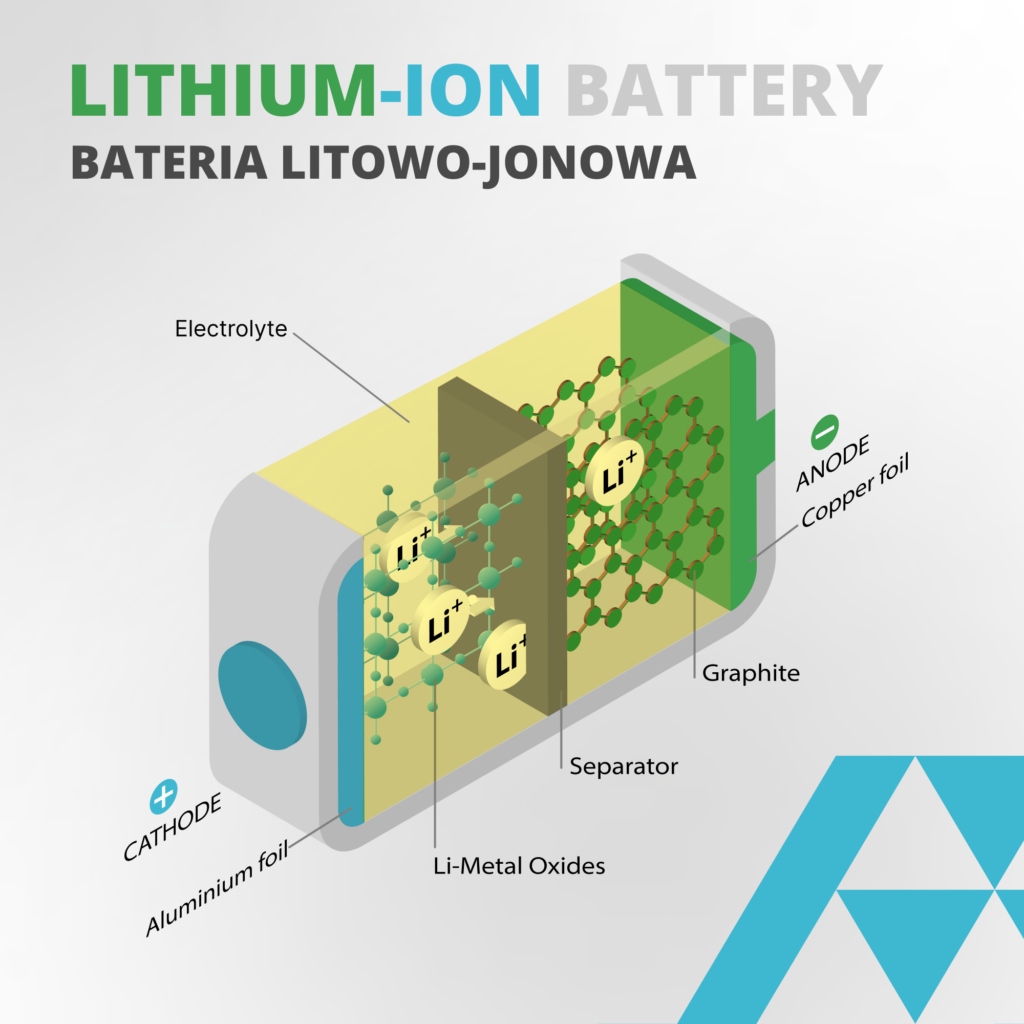

Lithium-ion batteries are a staple of modern technology used in many electrical devices, from smartphones to electric cars and energy storage. One of the most important elements of their design is the electrolyte, which allows lithium ions to flow between the anode and cathode. Its quality affects battery life, performance and safety.

The electrolyte in lithium-ion batteries performs a key function enabling energy storage and transfer. Its function is to transport lithium ions between the anode and cathode, which is essential for the battery to function properly. This process makes it possible to store energy and release it efficiently, such as during the operation of an electric car. The electrolyte also plays an important role in stabilizing the surface of the anode and cathode, which extends the life of the battery and improves its performance. The quality of the electrolyte thus has a direct impact on the range and efficiency of electric cars.

Battery longevity - benefits for users and the environment

Studies show that a properly selected electrolyte can significantly extend the life of lithium-ion batteries, which in electric cars can last from 3 to 10 years. Recently, a minimum life of 10 years has been required of batteries used in energy storage. The rate of degradation of automotive batteries, averaging 2.3% of original capacity per year, can be slowed by using a premium electrolyte. After 500 charging cycles, battery capacity drops to about 90%, and after 1,000 cycles to about 80%. A charging cycle for an average passenger electric car takes 4 to 5 days, resulting in 74 to 91 charging cycles per year. It thus takes 10 to 14 years to achieve 1,000 charging cycles. At GTHR Poland, our electrolyte supports the long life of batteries, which has a direct impact on reducing EV operating costs, CO 2 emissions and, consequently, environmental protection.

Technology of the future - lithium-ion batteries

Technological advances are allowing the development of increasingly efficient lithium-ion batteries. Modern raw materials are helping to improve safety and extend battery life. At GTHR Poland, we are constantly working to improve our products to meet the growing demands of the electromobility market. Lithium-ion batteries are not only an efficient energy source, but also a key technology for sustainable development. Thanks to the production of modern electrolyte, we offer products that meet the highest safety and performance standards.